CO2 Dry Ice Blasting & Industrial Cleaning Services

Since 2002

Process Equipment Cleaning, Factory Cleaning, Motor Cleaning & Restoration, Mold Remediation and Fire Restoration for the Southeast including Alabama, Florida, Georgia, North Carolina, South Carolina, and Tennessee.

CO2 Dry Ice Blasting Cleaning Applications

Dry ice blasting is used to safely clean equipment including electric motors and generators, variable frequency drives, presses, ovens, conveyors, etc. with minimal to no disassembly required.

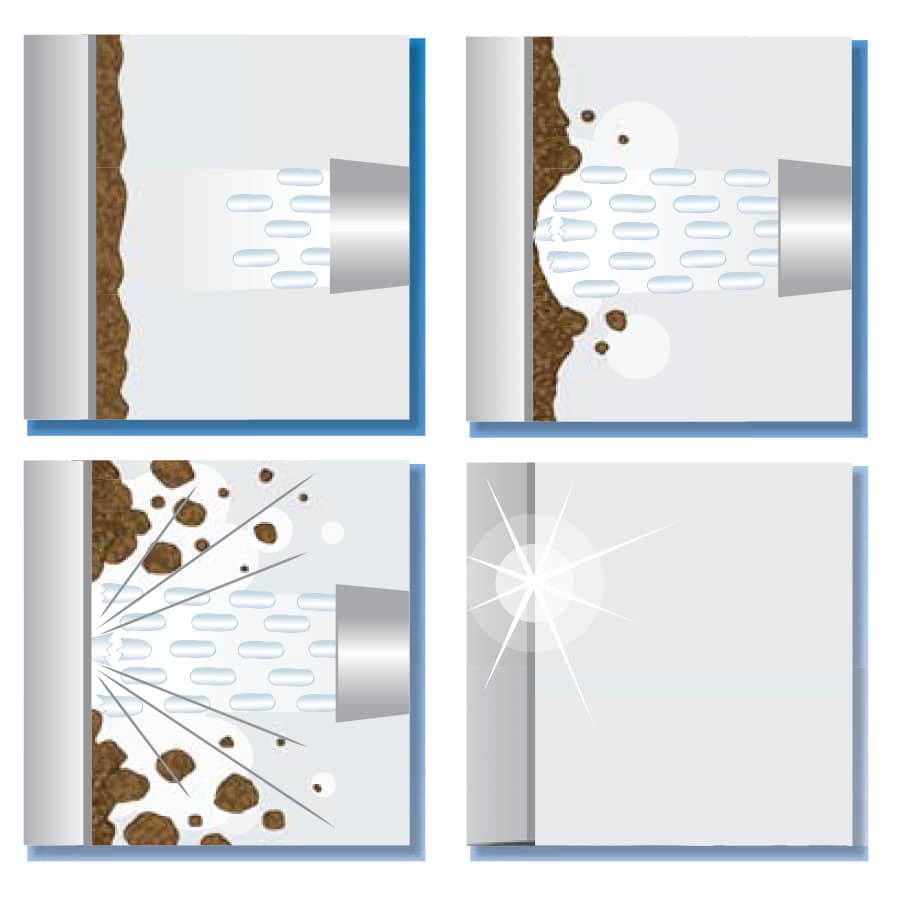

How Does Dry Ice Blasting Work To Clean?

Dry ice blasting involves propelling pellets at extremely high speeds. Dry ice blasting cleans surfaces through a combination of kinetic energy, extreme temperature change and sublimation (the solid dry ice conversion to gas).

The Benefits of Dry Ice Blasting for Cleaning

The unique advantages of dry ice blasting include decreased downtime, safe for all equipment, sanitary and clean, environmentally friendly and flexible. Approved medium by the EPA, USDA, FDA, AIB and GFSI inspected /certified facilities.

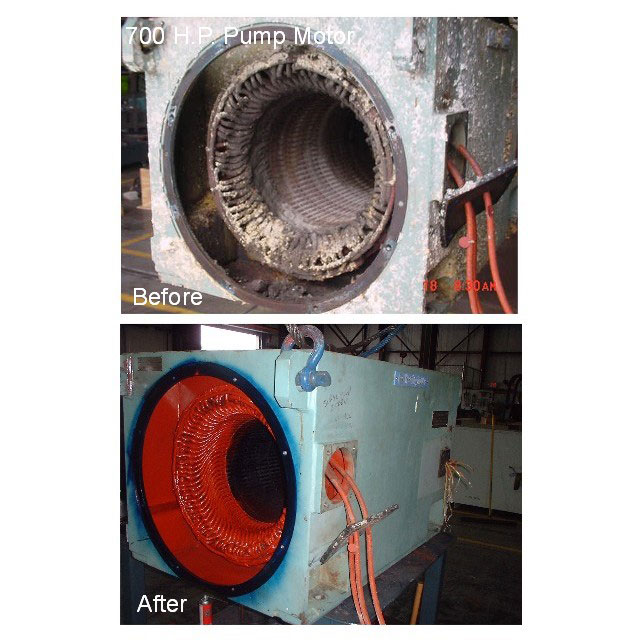

Industrial Cleaning Projects

Thank you again for such a well trained staff that made my job as the Safety Technician for this project easy.

I would recommend CO2 Blasting to anyone who sees a need for fast, efficient, and safe cleaning of industrial equipment.

Their expertise on the fragile windings of some motors they have cleaned for us and the results of their work is always impressive.

Without Co2 Blasting’s service we would lose valuable production time and lose money due to premature equipment failure. I highly recommend their services.